With us your ideas become reality

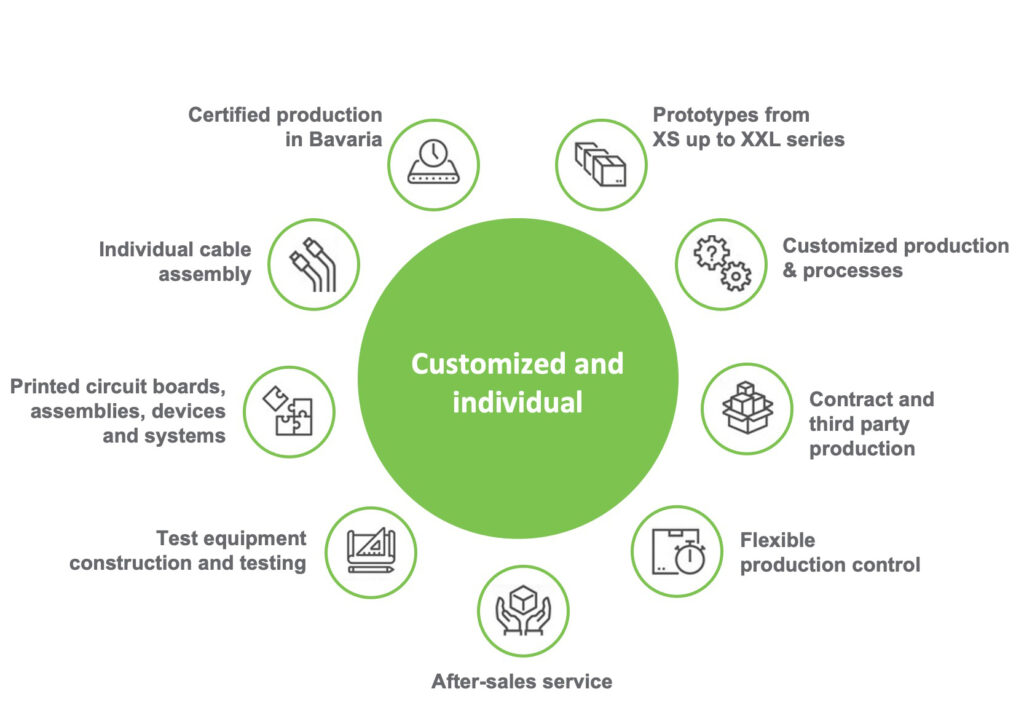

We always develop with production in mind. After all, what is the point of creating the perfect plans if they cannot be realised cost-efficiently? In this respect, you can rely on our decades of experience and our large network to take your product into production.

What is also important here: the close dialogue with you, our customer. Together with you, we will find the best possible. Quality and reliability is of course the basis of our work.

Quality managed in Germany

Many factors matter in choosing the right production partner and manufacturing location: qualification, quantity, logistics, quality and of course costs. We weigh up these points in close collaboration with you and together we find the ideal location, wether in Eastern Europe, Asia or in our own factory in Bavaria.

We take care of everything: development, modification, approval, quality and testing. In short, we assume complete responsibility for the production, from start to finish.

Martin Bauer

Head of Production

How can we help you?

Let's talk about your challenges!

Contact us

Flexible and prepared even for difficult work:

Our facility in Bavaria

Our production is located in Wernberg-Köblitz, Bayern.

There, on 1500 sqm, we produce more than half a million assemblies every year – both in-house developments and commissioned/contract manufacturing for other companies.

Our key strength: flexible adaptation to the needs of our national and local customers. All with the aspiration of professional series production.

Our production – facts

- Location: Wernberg-Köblitz, Bavaria

- Production area: 1,500 sqm

- Assembly production, cable assembly, device production and installation

- In-house and external production

- Specialised in the flexible production of very small, small and medium-sized series

- As a package with other MCS services or as an individual service

- Over 500,000 articles and assemblies per year

- State-of-the-art machinery

- ISO 9001-2015 certified

- KBA approval (product-specific)

- UL-certified (product-specific)

Looking for production support?

We also support companies with or without their own production when manufacturing exceeds their possibilities or capacities. Or for cable assemblies, standard components, fluctuating quantities or the production of very small or small series.

Quality, flexibility and short response times

Our core values are of course also apparent in production: extensive customisation, flexibility and integration into existing processes and systems. Whether we produce our own developments or take on contract manufacturing, we can react flexibly and quickly to changes.

Whether it’s the number of pieces or the time frame, we are guided by you and are ready to respond even if your plans take a turn during the process.

-

Focus: Assembly and module production

We produce mechanical and electronic assemblies and functional units for you – adapted to your individual requirements, e.g. in the form of SMD/THT PCB assembly. To accomplish this, we use a range of technical processes that are precisely matched to the complexity of the task at hand.

Contact us and find out how we can help you.

Technical processes

- Soldering processes: Reflow soldering, wave soldering, vapour phase soldering, hand soldering

- Ultrasonic welding

- Coating and potting of circuit boards and cables

Project examples for assembly production

- Special hand soldering for HF antennas of medical devices

- Batteries, circuit boards, cables for the construction of awnings

- Evaluation electronics for soil density measuring methods

- Sensors for car park monitoring

-

Focus: Cable production and assembly

In the field of cable assembly, we offer you a wide range of products from single wires to complex cable harnesses, customised to your specific requirements.

Contact us and find out how we can help you.

Project examples for cable production and assembly

- Prototypes and complex cable harnesses for automotive development

- Re-pinning of finished cable applications with hotmelt overmoulding

- Development of special connector systems for LED lighting in guide rails

- Cable assembly for dispensing technology and sensor technology

-

Focus: Equipment manufacturing and installation

Here we combine mechanical and electronic components into modules and functional units of complex devices and systems. These can either be further assembled or used immediately. We do this with comprehensive know-how and many years of experience.

Contact us and find out how we can help you.

Project examples for equipment manufacturing and assembly

- Project examples for device production and assembly

- Printer systems

- Assembly of traffic guidance and display systems

- HMI units

- Measuring devices

-

Testing: 100% quality guaranteed

Our test procedures ensure reliable results.

- Typical procedures are functional and assembly tests, AOI, IC, etc. with our own test equipment.

- For cable assembly: crimp height measurement, pull-off test, insulation, continuity and high-voltage tests.